Maintaining an effective environmental monitoring system is crucial for the pharmaceutical and healthcare industries to protect their products, profits, and patients. For example, many pharmaceutical products require storage at specific temperatures to remain stable and effective. Unfortunately, many pharmaceutical products undergo chemical changes if stored at temperatures too high, and pharmaceutical companies must embrace robust temperature monitoring procedures to manage prevention.

Environmental monitoring is a process that incorporates many layers of pharmaceutical cold storage systems. It includes creating supply chains that facilitate environmental monitoring procedures and educating healthcare workers on how to collect environmental data in storage facilities.

Use Environmental Monitoring to Establish Cold Chain Storage Systems

For transporting pharmaceutical products from manufacturers to healthcare facilities, companies must establish temperature-controlled supply chain procedures that keep products at stable temperature ranges. However, that can be challenging since products often pass through different storage facilities and shipping containers before reaching their destinations. Moreover, upon receiving pharmaceutical products, healthcare workers must know how to handle and store them.

These temperature-controlled supply chains are known as cold chain storage. Due to the COVID-19 pandemic and ensuing policy decisions, cold chain storage has become an area of interest for investors, especially since worries regarding supply chain reliability are still looming today.

COVID-19 vaccines require precise storage temperatures, highlighting the importance of cold chain storage. In particular, the Pfizer COVID-19 vaccines need ultra-low temperature storage conditions to remain effective. Unfortunately, traditional freezers and cooling systems can not reach these temperatures.

As a result, Pfizer has devised its storage containers that use dry ice to keep temperatures extremely low. In addition, the containers have an environmental monitoring system that tracks internal temperatures. Storage and shipping challenges have been central to the deployments of Pfizer’s vaccine since the company first began negotiations with national governments to supply them.

Let’s explore the many tactics pharmaceutical companies like Pfizer use to make these environmental monitoring systems effective.

Data Loggers for Environmental Monitoring Systems

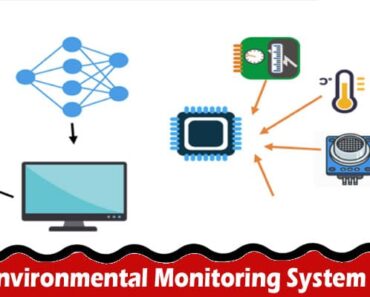

Data loggers are small electronic devices that measure and record environmental conditions such as temperature, humidity, and differential pressure. They are crucial for creating effective environmental monitoring systems because managers can determine if improper temperatures exposed the pharmaceutical products by reviewing the temperature data they collect.

According to Dickson Data, data loggers are also crucial for environmental monitoring systems regarding compliance. For example, many regulators require data loggers to record storage temperature ranges to prevent defective products from being distributed or administered to patients. As a result, installing, maintaining, and extracting data from data loggers is essential to many companies’ quality assurance and compliance best practices.

Environmental Monitoring Systems and Temperature Mapping

In many cases, it is not enough for companies to set up a data logger in each storage facility to establish an effective environmental monitoring system. As a result, temperatures within the same storage unit can vary depending on the unit’s placement, ventilation, and other factors. Therefore, it’s entirely possible for products in one part of the unit to be at appropriate temperatures while products in a different part are not.

To solve this problem, companies must often set up several data loggers in different areas within the same storage facility. These data loggers will give managers a picture of the different temperatures within the facility and allow them to create a temperature map of the unit.

Temperature mapping allows supply chain professionals to oversee all temperature ranges that pharmaceutical products are exposed to and create an effective environmental monitoring system. In addition, powerful software can manage and analyze temperature mapping information to develop cold chain storage oversights.

Internet-Connected Data Loggers

Another challenge pharmaceutical companies are grappling with is creating environmental monitoring systems that alert them when storage temperatures fall outside appropriate ranges. Moreover, establishing alerts in a centralized alert management system gives leadership a clear and immediate picture of temperature changes.

To meet this challenge, many companies are turning to internet-enabled data loggers which transmit temperature data online. Many of these data loggers can be programmed to transmit temperature data in real time and give immediate alerts if temperatures are outside acceptable ranges.

Internet-connected environmental monitoring devices and IoT devices are part of a new wave of technology that seems likely to shape our personal and business lives in the coming years.

Companies should have a straightforward change management process that defines the chain of command and RACI chart for dealing with temperature storage deviations. Therefore, companies can quickly address supply chain problems and draw accurate conclusions from environmental data. Pharmaceutical companies should also set priority levels that define cold chain storage problems with the highest priority.

To sum up, establishing an effective environmental monitoring system is a multifaceted process. It includes utilizing proven environmental monitoring technologies like data loggers and setting up organizational checks and balances to respond to mishaps.