The technology of laser machining utilizes laser beams of a higher power, varying in width for an extensive range of applications like cutting, slitting, and creating holes. This method is used in diverse kinds of fabricated, for instance, plastics, metals, marble, glass, and vinyl. Other materials that are being fabricated employing this technology take into account nylon, carbon fiber, ceramics, malleable rubber, and thin metal foils.

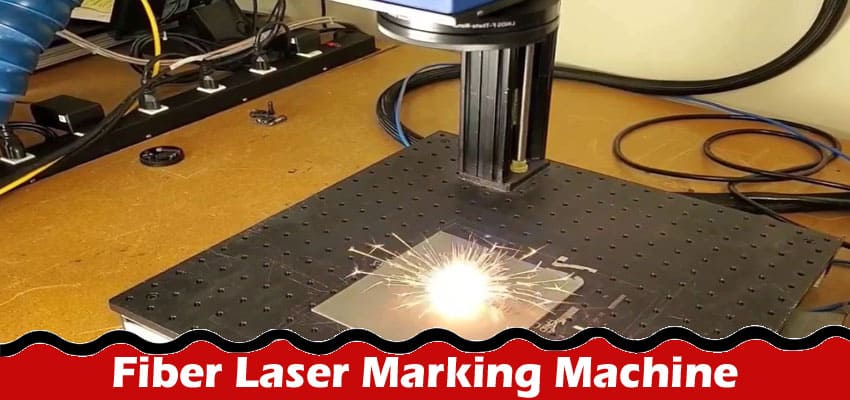

The procedure of a fiber laser marking machine involves a fiber optic shaft of light and straight delivery systems to allow precision positioning through the process of cutting metal or other interrelated materials. It is also employed in cutting free parts, required in industries like aerospace, motor vehicle, and others. The procedure is competent and fast and cuts to a specific depth devoid of severing any sort of material from the work part.

The Utility of Machining

It is also utilized for producing coarse surfaces on hard materials like metals and delicate materials like ceramics/glass. The equipment helps mark the surfaces of materials. In this procedure, an intense laser beam is in fact passed right through the mirror stencil and on top of the material part that is being marked.

Even though it has been proven helpful in many ways, yet research is in progress for the development of superior laser machining techniques by the best fiber laser cutting machine manufacturers to allow minute device production to be used in medical manufacturing to fight against fatal diseases like malignancy.

A Fiber laser marking machine plays a vital part in the manufacturing procedure. This is why it is necessary to adopt a qualitative approach to make use of the most excellent machining method in the marketplace. That’s precisely where machining based on laser technology comes to aid one and all. Though it has a very important role to play in the current manufacturing scenario, yet a large majority still like better the processes of customary machining.

Enormously Valuable Machinery

Customary machining though in use yet is less competent than laser machining which has been utilized for the diverse manufacturing process, nowadays. This technology allows the unproblematic removal of solid substances with the aid of a laser beam. The basic elimination process depends on optical matter properties and this establishes how much energy is being absorbed by the resources. Furthermore, the laser pulses are tremendously easy to control. In short, this type of machining is extremely important in research activities and manufacturing industrialized processes.

In view of the fact that no chemicals are used, this machining can manoeuvre efficiently and is environmentally gracious. It can be easily automated by employing using robots. The laser pulse does away with coatings, cleans metal surfaces, and prepares the outside for more painting activities. Even though it may cost a lot on capital outlay, yet it is lower than any customary method that is being used for related purposes in the marketplace.

This machining works significantly on unfinished work pieces than coarse techniques. All through its processes, the carbon fibers are not smashed. It is a much better choice as compared to any available customary system in the present-day marketplace. So, if you would like coating elimination, hole drilling, or engraving, this equipment can give you the most advantageous results to meet your manufacturing needs.

The past many years have seen noteworthy advances in both the performance and application of manufacturing laser systems. From the beginning of the Ytterbium fiber laser to ongoing developments in the performance and consistency of more traditional laser sources, there has certainly not been such an extensive range of laser technologies made available by most fiber laser cutting machine manufacturers.

By way of shorter pulse widths, higher peak dominance, and higher persistent power at higher pulse rates, the Ytterbium fiber laser drastically improves the performance of the getting on solid-state lasers. The Ytterbium fiber lasers are air-cooled, make available 100k+ hours of diode existence, and are highly consistent with zero needed maintenance.

CO2 Laser Designs

Effectiveness and consistency improve with New CO2 Laser Designs. The most up-to-date CO2 laser designs make available more power in smaller packages amid lower functioning costs and are time and again air-cooled. Improvements in laser beam excellence and pulse characteristics have enlarged the capabilities of this time-proven equipment. The cost-per-watt of today’s solid designs makes available a striking, lucrative solution for many industrialized challenges.

For laser marking systems and other matter processing applications that make the most of galvanometer beam-steering systems, the most modern scan systems make available unparalleled speed and precision. Increased process swiftness may notably improve the cost-savings of a laser device tool as compared to earlier laser performance and other matter processing applications that make the most of galvanometer beam-steering systems, the most modern scan systems make available unparalleled speed and precision. Increased process swiftness may notably improve the cost-savings of a laser device tool as compared to earlier laser performance.

Developments in technology have made easy today’s laser improvements in customary applications and the development of ground-breaking new laser processes. Higher speeds, better precision, and higher quality – everything continues to develop innovative uses for the most up-to-date laser technologies at same time as continually improving on the benefits of lasers in conventional applications.